Yam

New Member

Posts: 585

|

Post by Yam on Feb 4, 2017 10:55:06 GMT -5

I'm bored and am considering creating non skid molds for my boat. I have a few areas that could be better but don't really need attention. Thus this is solely a project that is for fun.

To make the mold, I will remove my anchor locker door and do it in the warm house. I understand I need to use PVA as a mold releasing agent and plan to make a few small molds with bondo.

Anybody ever do this? Any thoughts?

|

|

|

|

Post by drag4striper on Feb 4, 2017 11:30:17 GMT -5

That's a good February project.

Have you ever considered SeaDek?

If you would rather produce your own the SeaDek website has a short video about creating a template for your deck.

It may help you, just a thought.

|

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 4, 2017 12:05:41 GMT -5

That's a good February project. Have you ever considered SeaDek? If you would rather produce your own the SeaDek website has a short video about creating a template for your deck. It may help you, just a thought. That stuff looks great! I have checked it out before. I'm just simply wanting to learn how to restore existing non skid. I'm pretty good with gel coat and if I can get the non skid stuff down, then I feel like I can do anything to my boat without any worries. |

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 14, 2017 15:40:56 GMT -5

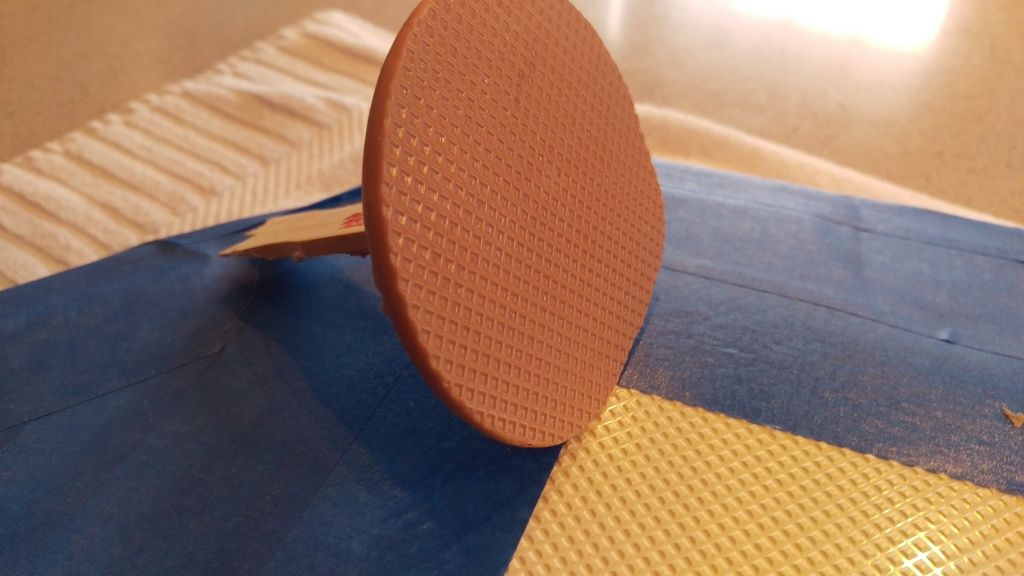

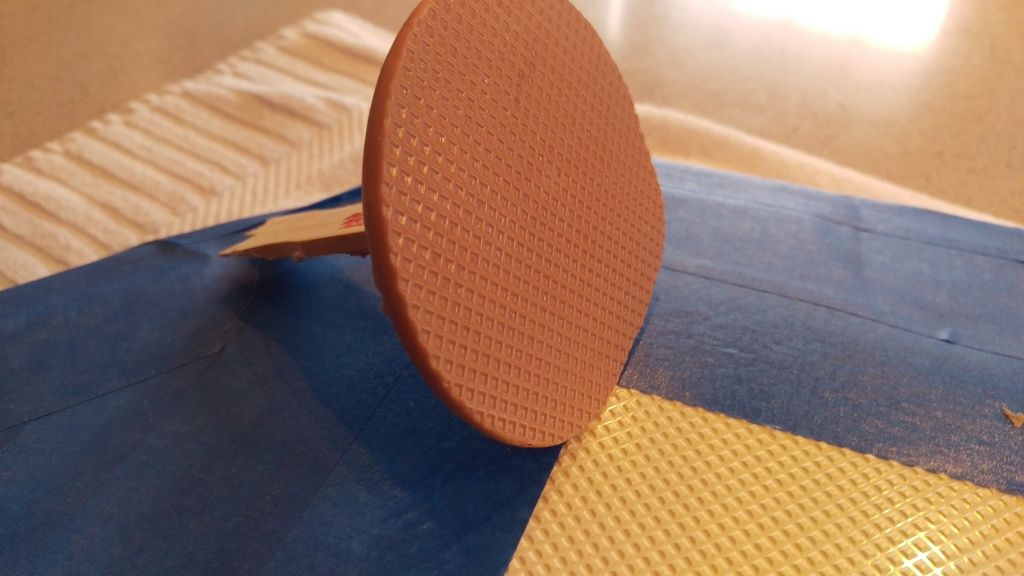

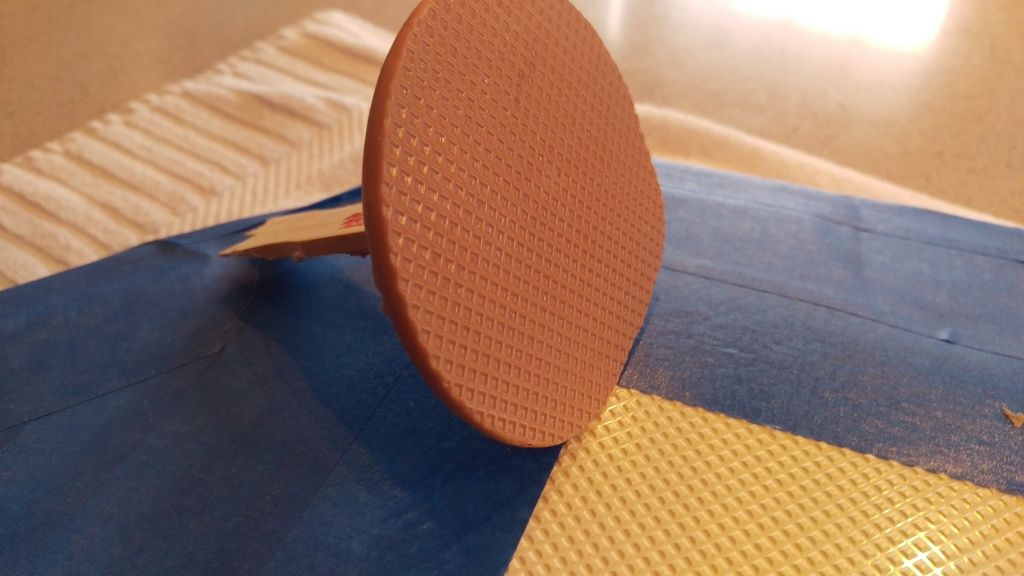

This is what I wanted to do and as shown, now I have done it. This is the female impression of my non skid surface of my boat. Now I can repair a few spots and a couple screw holes on my non skid surface. I simply sprayed PVA on the surface then slapped down some bondo and put a stir stick in it. The mold locks into place for repair areas. So now, I will just do a typical gel coat repair and slap the mold down to get a perfect match. Fun!  |

|

|

|

Post by archenemy on Feb 14, 2017 17:25:33 GMT -5

This is what I wanted to do and as shown, now I have done it. This is the female impression of my non skid surface of my boat. Now I can repair a few spots and a couple screw holes on my non skid surface. I simply sprayed PVA on the surface then slapped down some bondo and put a stir stick in it. The mold locks into place for repair areas. So now, I will just do a typical gel coat repair and slap the mold down to get a perfect match. Fun!  Yam you must have extra large balls to put bondo down on that pretty deck of yours. I have used PVA with success in the past but I wouldn't bet my deck on it. Always pushing it aren't ya 😉 |

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 14, 2017 17:51:04 GMT -5

This is what I wanted to do and as shown, now I have done it. This is the female impression of my non skid surface of my boat. Now I can repair a few spots and a couple screw holes on my non skid surface. I simply sprayed PVA on the surface then slapped down some bondo and put a stir stick in it. The mold locks into place for repair areas. So now, I will just do a typical gel coat repair and slap the mold down to get a perfect match. Fun!  Yam you must have extra large balls to put bondo down on that pretty deck of yours. I have used PVA with success in the past but I wouldn't bet my deck on it. Always pushing it aren't ya 😉 That's why I used my anchor locker door to experiment. I also bought a cheap airbrush to spray on 3 coats of PVA along with applying a mold release wax. The bondo was hard as a rock in 10 minutes and I was worried as hell because I have never used it before. That stuff is badass! However, it came off with zero effort and brought the PVA with it. The PVA was like cellophane. "Yam's Useless Boat Repair Shop" is now open for business! |

|

|

|

Post by archenemy on Feb 14, 2017 17:58:49 GMT -5

Yam you must have extra large balls to put bondo down on that pretty deck of yours. I have used PVA with success in the past but I wouldn't bet my deck on it. Always pushing it aren't ya 😉 That's why I used my anchor locker door to experiment. I also bought a cheap airbrush to spray on 3 coats of PVA along with applying a mold release wax. The bondo was hard as a rock in 10 minutes and I was worried as hell because I have never used it before. That stuff is badass! However, it came off with zero effort and brought the PVA with it. The PVA was like cellophane. "Yam's Useless Boat Repair Shop" is now open for business! We'll have you ever looked at the price of the molds ? That stuff is way too pricey for me. I'm gonna try your method and if my Bondo sticks to the deck I'll send you a bus ticket so can come down and get it off ! 😀. Nice work yam |

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 14, 2017 18:07:21 GMT -5

That's why I used my anchor locker door to experiment. I also bought a cheap airbrush to spray on 3 coats of PVA along with applying a mold release wax. The bondo was hard as a rock in 10 minutes and I was worried as hell because I have never used it before. That stuff is badass! However, it came off with zero effort and brought the PVA with it. The PVA was like cellophane. "Yam's Useless Boat Repair Shop" is now open for business! We'll have you ever looked at the price of the molds ? That stuff is way too pricey for me. I'm gonna try your method and if my Bondo sticks to the deck I'll send you a bus ticket so can come down and get it off ! 😀. Nice work yam Keep in mind this is a quick solution for very small repairs. If you want to create a bigger mold, I would use gel coat rather than bondo. You can back the gel coat with fiberglass chop strand with hardener and peel it right off after everything sets up. Takes an entire day though. This method took less than an hour. |

|

Brian

New Member

Posts: 611

|

Post by Brian on Feb 15, 2017 7:27:36 GMT -5

That looks great. Now, if you can match shades of white, you are a better fiberglass man than me!

|

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 15, 2017 13:56:00 GMT -5

That looks great. Now, if you can match shades of white, you are a better fiberglass man than me! I'm a "get the factory gel coat" kind of guy. I watched a video on color matching and I'm quite convinced that I could have gel coat delivered from South Carolina faster than I could create a match. |

|

Gator

New Member

Posts: 1,534

|

Post by Gator on Feb 16, 2017 13:40:45 GMT -5

That's a nice looking ping-pong paddle!! Except you put the handle in the wrong place.....

|

|

|

|

Post by mwardncsu on Feb 16, 2017 21:48:59 GMT -5

That's a nice looking ping-pong paddle!! Except you put the handle in the wrong place..... You know Yam - he has to do everything different....  |

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 21, 2017 15:39:58 GMT -5

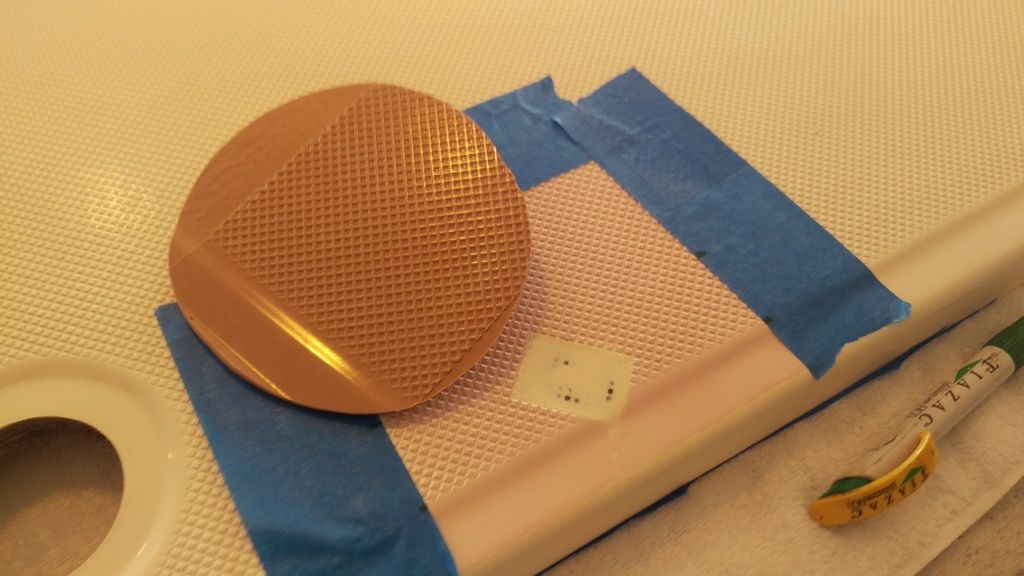

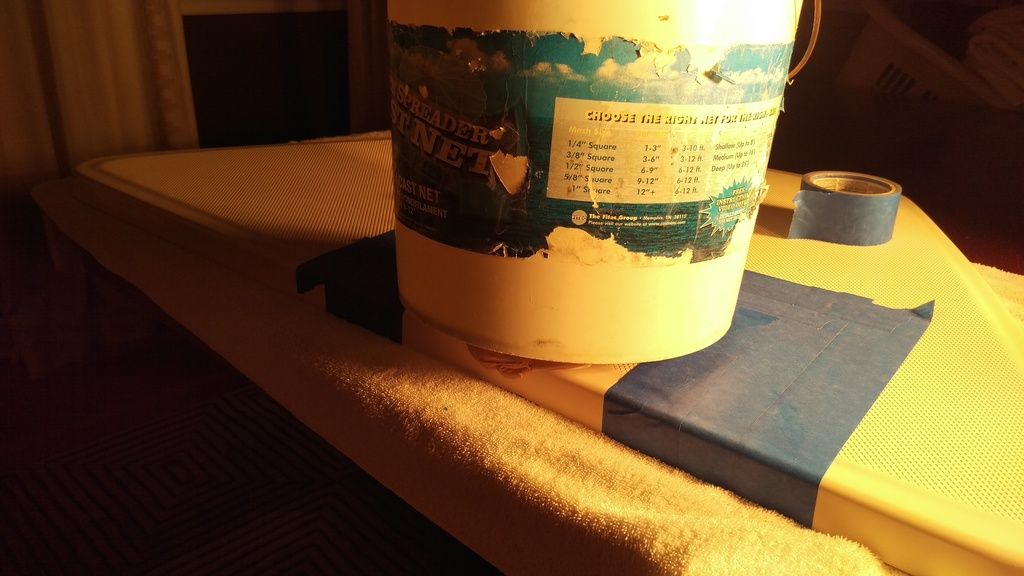

OK... So I decided to repair some non skid. My problem was that the pattern fades as it nears the edge. As a result, my ping pong paddle mold would not work. Thus, I created this cool mold that not only fades into the pattern, it locks and lines up perfectly using the edges of the lid. Fun!  |

|

|

|

Post by coheasion on Feb 21, 2017 15:49:57 GMT -5

Your idea of fun may be just a tad bit different ;-)

|

|

Yam

New Member

Posts: 585

|

Post by Yam on Feb 23, 2017 21:45:43 GMT -5

Well, it's been a series of setbacks here at "Yam's Useless Boat Repair." A very tiny repair has grown into a rather large one. I have learned many things though. First, don't grind down more than an eighth of an inch below the surface if you want the gel coat to fill in evenly. Second, make sure to cut off and round the edges of the mold so that it will lock into place and not shift during curing. Third, use a heat lamp to speed up the curing process. Fourth, don't ever do this if your half as anal retentive as I. And finally, weight down the mold to ensure the pattern does not appear raised. The first shot below shows what some might consider a successful attempt. However, you can clearly see the raised pattern. The next two shots illustrate my solution. That is, I bondoed a platform to a new mold and placed 25 pounds of water on it. I am now patiently awaiting to see if this works! I can hardly wait for the morning to come!    |

|